today’s cyclodextrin:

It’s been just a few days since I heard a lecture that proposed using CDs in 3D printing pharma applications. In this paper from the South China University of Technology and Nanyang Technological University Singapore, 3D-printed wearable sensors are introduced.

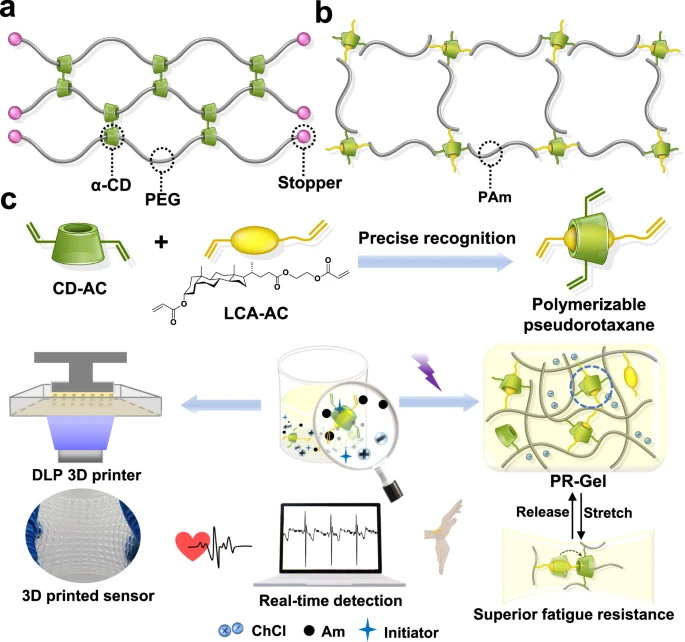

While hydrogels enable a variety of applications in wearable sensors and electronic skins, they are susceptible to fatigue fracture during cyclic deformations owing to their inefficient fatigue resistance. In this work, acrylated β-cyclodextrin with bile acid is self-assembled into a polymerizable pseudorotaxane via precise host-guest recognition, which is photopolymerized with acrylamide to obtain conductive polymerizable rotaxane hydrogels (PR-Gel). The topological networks of PR-Gel enable all desirable properties in this system due to the large conformational freedom of the mobile junctions, including excellent stretchability along with superior fatigue resistance. PR-Gel-based strain sensors can sensitively detect and distinguish large body motions and subtle muscle movements. The three-dimensional printing fabricated sensors of PR-Gel exhibit high resolution and altitude complexity, and real-time human electrocardiogram signals are detected with high repeating stability. PR-Gel can self-heal in air, and has highly repeatable adhesion to human skin, demonstrating its great potential in wearable sensors.

#motionsensor #selfhealing

See the full article here: Polymerizable rotaxane hydrogels for three-dimensional printing fabrication of wearable sensors